E-Commerce / Technologie pro E-Shopy

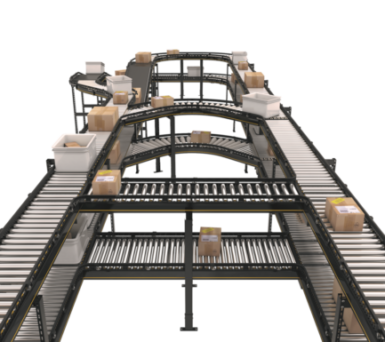

We offer design solutions using belt and roller conveyors in operation and interoperation transport, including both continuous and discontinuous modes of transport. Our conveyor systems feature a high degree of modularity, which provides flexibility in changing material flow schemes.

Key products:

- Smooth belt conveyors

- Modular belt conveyors

- Gravity roller conveyors

- Driven roller conveyors

- Accumulation conveyors

- Chain conveyors

- Belt curves

- Telescopic belt conveyors

- Modular systems

Vertical systems

We offer vertical transport systems for continuous and discontinuous operation. This includes all the safety features related to vertical transport (protective fencing, optical safety components).

Key products:

- Lifts

- Elevators

- Spiral conveyors

- Elevation tables

Storage systems

We offer storage solutions for pre-production storage of material, work-in-process storage and inventory, and distribution warehousing and dispatching. Comprehensive range of racking systems for static and dynamic storage. Dynamic storage using the FIFO and LIFO methods fulfils the requirements for maintaining the required material flows. The degree of automation meets the demands on the storage process with regard to return on investment (ROI).

Key products:

- Static racking for pallets

- FIFO gravity roller racks

- LIFO gravity roller racks

- Gravity shelves for cartons and plastic boxes

- Dispatch tracks

- Automatic stackers

Picking

Picking is one of the key stages in handling goods in a warehouse. A comprehensive solution for picking a system from sending a request for removal from storage, removal of goods from the warehouse position, consolidation of the ordered order and dispatch of the consignment (dispatch). Picking technologies and procedures must correspond to the type of packaging, the turnover of the goods, the type of handling equipment and storage equipment. Process optimization with a focus on minimizing picking errors.

Key products:

- Static shelving systems

- Shelving roller systems FIFO, LIFO

- Shelving racks

- Slope shelves for cartons and plastic boxes

- Order pickers Bar and RFID code readers

Packing station

Logistic processes also include workstations where operations are carried out manually and operations involving partial or full automation. Workstations are individually designed, with an emphasis on the specific requirements for process and ergonomic design. Workstations are normally provided with equipment for quality control and safe packing of the dispatched goods.

Key products:

- Packing tables

- Strapping machines

- Packing equipment

- Machines for the production of filling materials

- Weighing systems

- Bar code and RFID readers

Sorting systems

Sorting lines for simple splitting of goods, or high capacity systems for sorting of goods and materials such as cardboard boxes, parcels, large letters, padded envelopes, packaged food, catalogue goods, multimedia products, clothing, etc. The sorting system and its output correspond with the number of inputs and outputs. The sorting technology includes feed and output conveyors.